hardness tester diagram|insize hardness tester manual : vendor TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . HOT NEW. 1 108,6K. Japa do Bundão transando de quatro em um vídeo caseiro MCMLXXXVI. 1 38,2K. Amy Yamaguchi a japa do bundão dando o cuzinho apertado de quatro MCMLXXXVI. 2 36,2K. JAPA DO BUNDÃO PornStar09. 8 21,6K. Japa do Bundão PACKSBRVIPOFICIAL.

{plog:ftitle_list}

WEBnovinhos gay Telegram channels, groups and bots. Channel and group links for novinhos gay. The results are grouped into three, the first tab contains all channels matching .

The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .

Description. The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C .

work instruction for hardness tester

wilson hardness tester manual

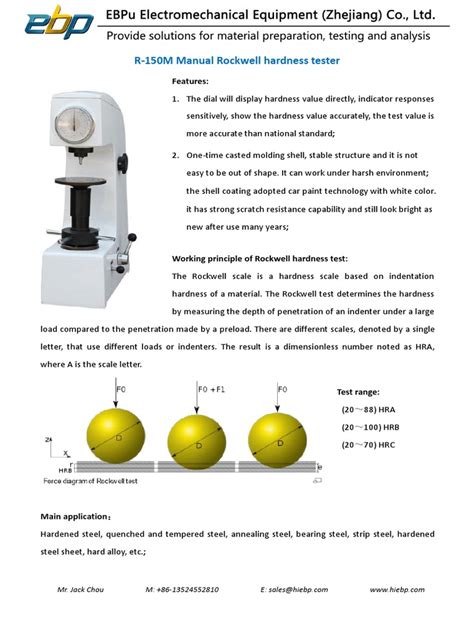

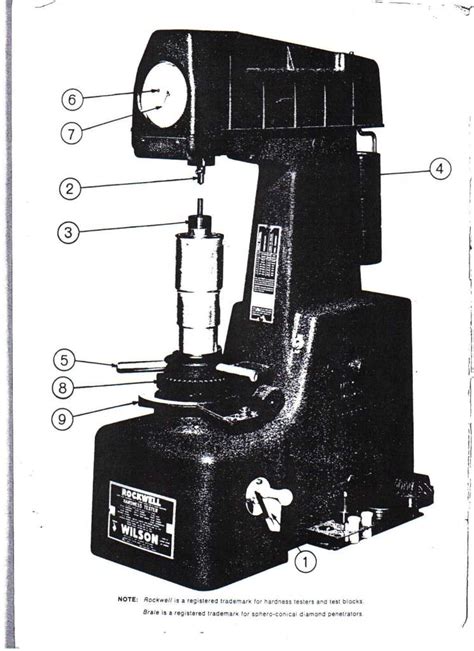

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .The hardness tester consists of fuselage, force exerting mechanism, measuring instructions and specimen support institutions and other components (see figure 1)。 Fuselage for a closed . Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron. In the standard method of the .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

this tester uses the standard test method for rockwell and Superficial rockwell hardness testing per AStM e-18. 2.1.1 Basic Operation 1. turn power switch on (back of the tester). the display .In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement . In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

After the test, the preliminary test force is removed and the indenter is removed from the test specimen. Types of Rockwell Scale Table-1 below gives the information on the type of indenter, the magnitude of the major load, and .The principle diagram of the rockwell hardness test Rockwell hardness test: Rockwell hardness test with the method of measuring pressure depth, hardness value through instructions direct reading, therefore, simple and convenient .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. .

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.Force diagram. The Brinell scale / b r . Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness.2.2 Testing principle 12 3 Technical capabilities 12 3.1 Specifications 12 3.2 Dimension size and weight 13 4 Testing 13 4.1 Preparation and Inspection prior to testing 13 4.2 Testing 15 5 Special prompts 18 6 Detail Testing procedures 19 6.1 Start-up 19 6.2 Turn on or turn off 19 6.3 Testing 19 6.4 Menu structure diagram 22

Ball indenter 1/16" Tungsten carbide ball (ø1.5875) Power cord For AC115V Hardness test block 60-65HRC Flat anvil ø64 mm Vinyl cover Hardness test block 90-95HRB V-anvil ø40 mm, Groove width 30 mm Manual Hardness test block 64-69HR30N Hardness test block 70-79HR30T Accessory BoxHardness Testing Considerations The following sample characteristics should be consider prior to selecting the hardness testing method to use: • Material • Sample Size • Thickness • Scale • Shape of sample, round, cylindrical, flat, irregular • Gage R & R Material The type of material and expected hardness will determine test method.Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

rockwell hardness tester manual pdf

Caution: The hardness tester will not open to its full capacity unless the elevation screw is allowed to pass through a hole on the support surface. 3. Bolt tester to support surface securely using the 4 each hex head bolts or use longer 10-1.5mm bolts if required. Be sure tester is level both front/back and left/right to 0.002 in/in.® Instruments RB2000 Rockwell® Hardness Tester Regular, Superfi cial, and Twin Scale Testing Technical Specifi cations Dimensions Model Number 2000R 2000S 2000T Preliminary Load Kg (N) 10 (98.07) 3 (29.42) 3, 10 (29.42, 98.07) .Hardness Testing. Wilson Instruments Buehler, with its Wilson line of hardness testers, is the global leader in hardness testing software, equipment and accessories. Buehler is proud to be the proprietor of 100-year old legacy brands including Wilson Instruments, Reicherter, and Wolpert, the innovators and founders of the hardness testing industry.Vickers hardness testing of small areas. A u: t o m a t i c e d i m e n s i o n s i b y . Hardness curve graph Hardness distribution diagram: Parts manager: 7 Multiple screen layouts for control, testing status, and result display. Pattern pasting Video .

Brinell hardness testing is particularly suitable for thicker, heterogeneous materials in the low to medium hardness range! Thin sheets cannot be tested with the Brinell hardness test! The Brinell hardness test .Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.

Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .3.1 Frame and anvil (See Parts Location Diagram on Page 8) The hardness tester has a cast iron frame (1). An elevating screw seat (18) is set on the stage at the front of the frame. The removable anvil (24) is set on the elevating screw (22), which is fitted precisely into the seat (18). The handwheel (21) elevates the elevating screw.Digital Rockwell Hardness Tester Instruction Manual 21 Industrial Ave • Upper Saddle River, NJ. 07458 Tel: (201)962-7373 • Fax: (201)962-8353 . See diagram 4.1. 4.3 Place the tester on a prepared platform, turn the hand wheel counter-clockwise to lower the anvil, remove the anti vibration pad; then place a precise level on the anvil .Moulding sand testing method explained with formula, animation, diagram, video, topic summary and PPT. Equipment and step-by-step method explained. . Equipment for the mould hardness test. Hardness tester. Specimen tube used to make sand specimen. Steps for taking moulding sand hardness test.

Hardness 600HV Indentation diameter 0.54mm 0.54mm 0.32mm 0.90mm 0.54mm Indentation depth 17μm 17μm 8μm 41μm 17μm Hardness 800HV Indentation diameter 0.35mm 0.35mm 0.35mm -- 0.35mm Indentation depth 10μm 10μm 7μm -- 10μm Available type of impact device D: General test DC: Hole or hollow-cylindrical test DL: Slender narrow groove or hole .Force diagram of Rockwell test A closeup of the indenter and anvil on a Rockwell-type hardness tester. The Rockwell hardness test can be conducted on several various hardness testers. [12] [13] All testers, however, fall under one of three categories. Bench model hardness testers can be found either in a digital or analog model.A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a measuring transducer. The DuraJet, ZHR Touchscreen and ZHR8150CL models are software controlled hardness testing machines with automatic .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

newage hardness tester manual

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

insize hardness tester manual

hardness tester for thin material

durometer tester with calibration certificate

Resultado da 5 min. 87%. Tufos' Premium HQ XXX Videos featuring the Hottest Pornstars are ALWAYS in high demand.

hardness tester diagram|insize hardness tester manual